Instant3DP – Instant Quote 3D Print

Model Stats:

| Support Material Volume: |

|

| Surface Area: | cm2 |

| Model Dimensions: |

x x

cm

|

| Total Path: |

|

Unit Price:

Details of Layer Height , Infill , Support , Tolerance

There are various Technology :

- FDM: 1-5 Days Process (depending upon model size and quantity)

- SLA: 2-4 Days Process

- MJF: 3-16 Days Process

- SLS: 3-16 Days Process

If the message came "HTTP 200". You may need repair the stl file.

If the same error occured after repairing stl file. Please mail us for quote price. Email ID- [email protected]

Other than any error code please Contact Us. or mail us.

You can upload your design file (.STL) file, choose technology & material to get instant quotes and you can place order online

- 3D Model:

stl,obj,stp,step,igs,iges, For best results in your 3D printing, we suggest uploading in .STL - 2D Image:

png,jpg,jpeg,gif,bmp(It will guide you to generate a lithophane based on the image) - Zip file

zipwith multiple 3D models

TIP: Save/export your models for upload preferably as STL file in "binary format" and with the unit of measurement "mm" , if neccesary, default file unit is mm,

click ‘inch’ to switch unit.

upload with a maximum file size of 100MB.

Yes, you can compress multiple parts(STL format only) in one ZIP Folder File

Or

please use our tool for Bulk Upload

Please click here to visit more details

Please visit our Manual 3D Print Tools to fill with your specific materials requirements.

Or

You can Contact Us.

Selecting the right filling density:

Based on the filling density, you can determine the stability (or also the weight) of your object.

TIP: “A filling of 20% is quite sufficient in most cases (due to a stable grid structure).”

- 10-30%: for models that are used for illustration or dimensional inspection.

- 30-60%: for models that are to be subjected to a certain mechanical load – e.g.: Functional tests

- 60-100%: for models that will be permanently exposed to mechanical stress – e.g.: Industrial use, stress tests, etc.

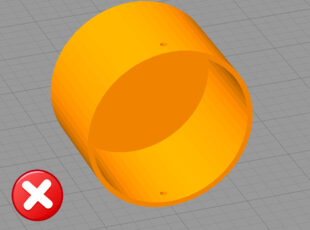

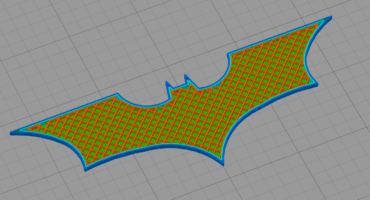

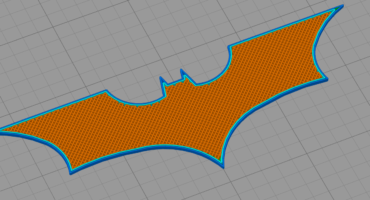

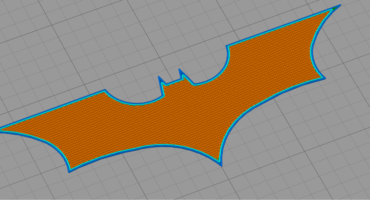

Using the graphical example, you can see how the fill density behaves within the closed object:

Infill 20%

Infill 50%

Infill 80%

Selecting the right height layer:

Your model is divided into many individual layers for the processing of our 3D printing process (FDM).

The height of the individual layers determines the subsequent “resolution” or the fineness/accuracy of your 3D print.

Therefore: “The lower the individual layer height, the finer or more multilayered the object is printed.”

However, the following should be taken into account:

- Halving the layer height inevitably leads to a doubling of the printing time.

- The compromise between the desired quality, the printing time and the resulting printing costs should therefore be thought through individually, because:

- Not all geometries necessarily require a low layer height to appear high quality. (Rounding require a significantly lower layer height than straight wall lines for a clean representation).

We available Layer height options for technology –

SLA – 0.03mm and 0.05mm

FDM – 0.1mm, 0.2mm and 0.3mm

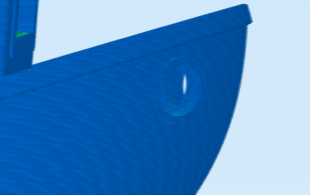

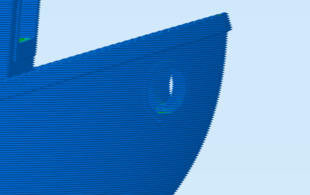

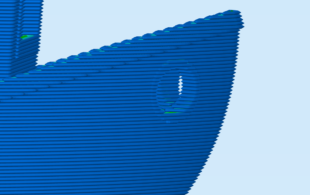

Using the examples, you can see what effects the different layer heights have on your object:

FDM

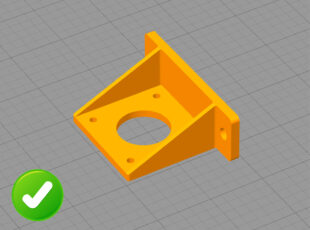

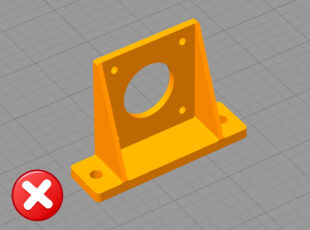

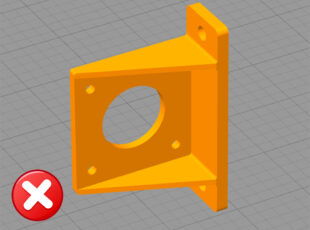

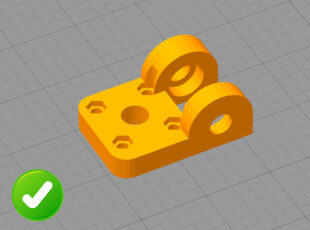

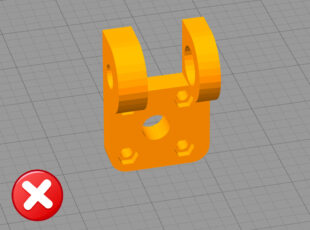

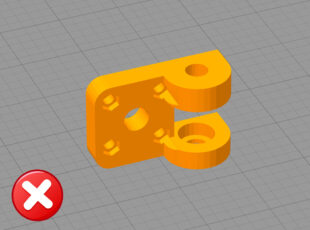

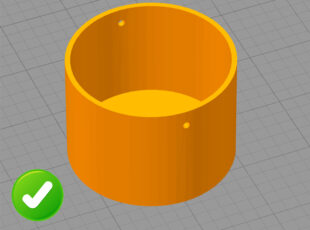

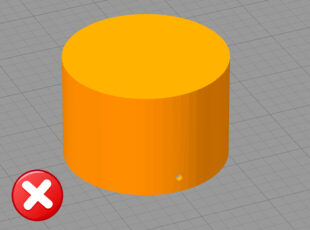

Place the model correctly:

Since the layer build-up in the FDM printing process always takes place “from the bottom up” (i.e. in the “Z-direction”), the layer course in the model can only be influenced by its orientation on the printing platform.

– In most cases, it is advisable to place the model as flat as possible or with the largest possible contact surface facing downwards on the platform.

– If possible, care should also be taken to print as little “support structure” as possible (this is needed for overhangs or slopes from approx. 50°). This reduces material consumption and therefore also printing costs.

– The printing direction has an effect on the appearance, quality as well as stability of the printed part.

– Therefore, align your model according to the geometry and/or the area of application: