MJF (Multi Jet Fusion)

MJF (Multi Jet Fusion)

Overview

Multi Jet Fusion is an improved manufacturing technique invented and industrialized by the corporation Hewlett-Packard (HP). It makes parts additively cheers to a multi-agent reproduction process.

Ultimate parts display quality external finishes, fine quality resolution, and extra consistent motorized properties when related to processes like choosy laser sintering.

The Multi Jet Fusion procedure is some of the quickest plastic 3D production technology. In contrast to SLS or FDM technologies, HP Multi Jet Fusion can 3D copy up to 10x quicker theoretically.

How does work process for MJF?

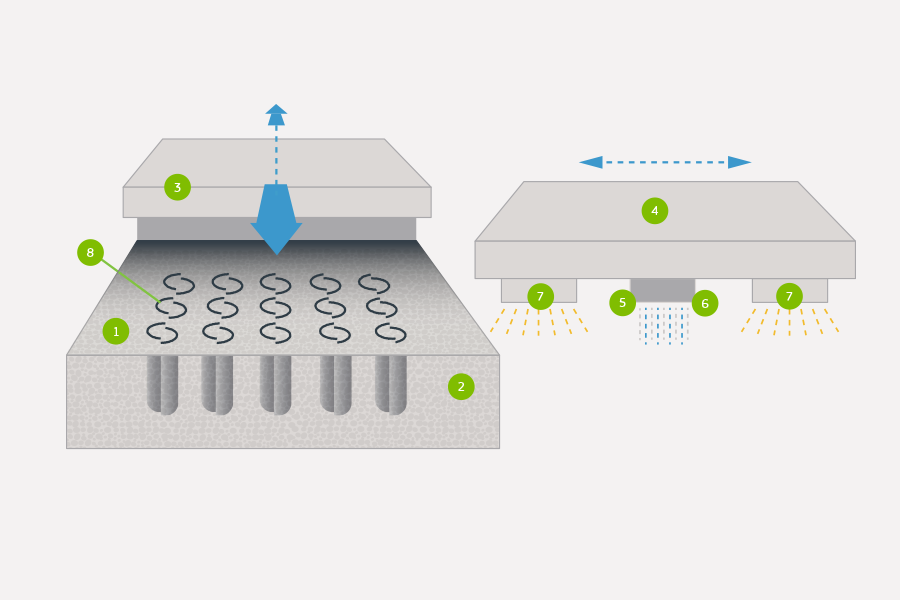

Multi Jet Fusion aids an inkjet collection to selectively put on detailing and fusing agents through a bed of nylon residue, which is at that time bonded by heating essentials into a hard layer. After an individual layer, the powder is dispersed on top of the cot and the procedure repeats until the function is complete.

When the production process is completed, the shape box is detached from the copier. The worker carefully takes out the parts from the shape box and eliminates the residual powder cheers to air blowers and brushes.

Benefits

Advantages

One of the best things about MJF is that it is fast. You can produce a part X10 very quickly than any other technologies. The MJF parts cost are low than SLA Technology.

Appreciations to this rapidity you can obtain your functions rapidly.

Why Choose Multi Jet Fusion For Your 3D Printing Project?

MJF offers engineering-grade materials with nice overall properties. besides, MJF offers increased surface finish, finer features, more consistent mechanical properties, and quicker build times.

Application

Multi Jet Fusion can make a complex and extremely detailed project in a very petite amount of period. Jet Fusion plastic is big for both new designers and knowledgeable specialists because of its excessive precision and little cost. It’s too much more tough and elastic than SLA published resin parts, and thorough than FDM published plastic parts.