Vacuum Casting

Vacuum Casting

Overview

Vacuum casting is an incredible method to make flexible or stiff parts, and is perfect for engineering testing, prototypes, and idea sealing as well as show demos. These parts could be produced using a number of casting polymers.

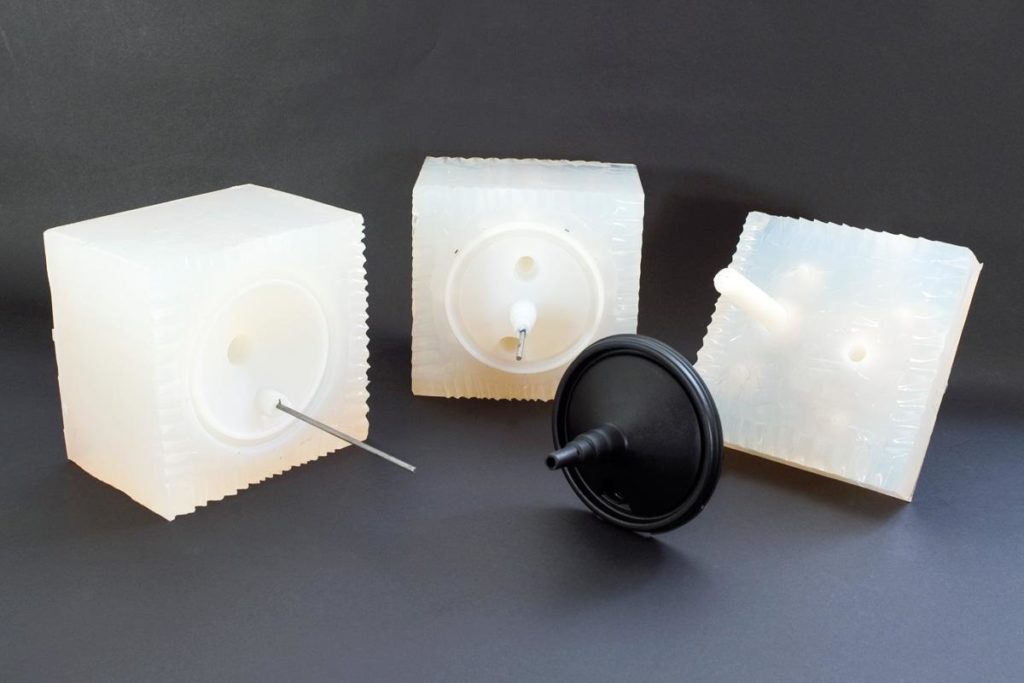

Vacuum casting is a technique for making low volumes of the parts shaped from low-cost silicone molds. Duplicates made along these lines show incredible fidelity and surface detail to the original prototype.

Vacuum casting is a moulding procedure for elastomers through a vacuum to pull the liquid matter into the mould. This procedure is applied when air inside causes hindrance, there are complicated details and undercuts, or if the matter is wire or fiber strengthened.

How does work Vacuum Casting?

Vacuum Casting starts by creating an ace model, normally utilizing Laser Sintering or Stereolithography, with high quality surface completion. At that point a silicone shape is created by casting the silicone around pattern, halfway under vacuum to keep away from air bubbles. After the process of curing, the silicone form is sliced by pre-defined separating planes and the ace is removed, leaving a cavity to make duplicates. Thus, Silicone mould can be recycled.

High pressure is used in some machines to make a pressure difference higher between the cavity of the mold and the mixing chamber.

Benefits

Advantages

- Low cost for molds

- Molds could be made in a couple of days

- Molds are durable for at least 20 duplicates

- Many kinds of polyurethane resins are easy to get to for casting, including over molding

- Cast duplicates are highly precise with brilliant surface texture

- Perfect for, rapid prototypes, samples, bridge to production, engineering models

Materials

Many casting polymers are industrially accessible to reproduce any possible surface texture and hardness. It is additionally possible to make parts that are completely opaque, translucent or totally transparent relying upon your application.

Elastomer

An elastomer is a polymer with viscoelasticity (i.e., together with elasticity and viscosity) and has extremely faint intermolecular forces, usually high failure strain and low Young’s modulus equated with further materials. The name, a multiple of a flexible polymer, is every so often use up interchangeably with elastic, though the last is chosen when mentioning to vulcanisates. To each of the monomers which connection to produce the polymer is typically a compound of numerous elements between oxygen, silicon, carbon and hydrogen. Elastomers are formless polymers kept overhead their glass change temperature, so that significant molecular recon formation, without shattering of covalent bonds, is possible.

Notes

a3dxyz is providing the best vacuum casting services and you can contact the experts at a3dxyz to know more about our services.