FDM 3D Printing Service

Fused Deposition ModelingFilament Fabrication (FDM/FFF)

Overview

Fused deposition modeling, or FDM, is an advanced type of production that habits additive industrial technology to yield 3D objects. Mutual applications comprise prototyping, minor-batch industrial and hobbyist utility.

With the help of FDM, you will be able to print not only functional prototypes however besides concept models and final end-use products. what’s smart regarding this technology that everyone parts printed with FDM will come in high-performance and engineering-grade thermoplastic, that is extremely useful for mechanic engineers and manufacturers. FDM is that the only 3D printing technology that builds elements with production-grade thermoplastics, therefore things printed are of excellent mechanical, thermal and chemical qualities.

The word “fused deposition modeling” and its FDM shortening is times trademarked by the designer of the procedure. So, the label bonded filament construction, or FFF, is too used as a precise synonym for this kind of printing. Together abbreviations and words are worked here. Some also term the procedure fused filament production.

Several kinds of 3D printing have been industrialized or are in growth, but FDM printing stays the greatest common and price-effective.

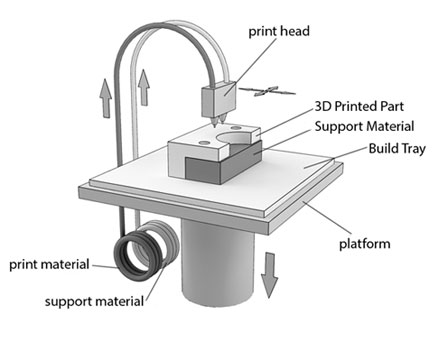

How does work FDM?

This process works by depositing the thermosetting polymer in filament form. This is done when the nozzle has reached a specific temperature and starts to melt.

The head is attached with a three-dimensional axis that lets it move in X, Y, and Z directions. The material that is melted is injected in thin strands. It gets deposited in layers on top of the previous one.

The layer then cools down and solidifies. The layer can also be cooled using the cooling fans attached to the extrusion head.

When a layer is set, the build platform moves down and a new layer is deposited on the pre-determined path. This process is repeated until the object is completed.

The FDM process uses durable materials that ensure the stability of the object. The production-grade thermoplastic materials that are used in this process can produce high-quality functional prototypes. Due to the high quality of FDM, it can also be used to produce durable manufacturing tools.

Benefits

Lower prices

Most of the time when companies select the FDM technology, the reasons behind it are the lower price and therefore the user-friendliness of this method. Compared to different techniques, FDM may be a lot cheaper. For companies, it’s important to understand whether or not manufacturing using 3D printing technique is cheaper than utilizing the standard approach of manufacturing. The powder that’s used in SLS and therefore the liquid for SLA are very pricey as an example. In contrast, for the material that’s utilized in FDM technology, the filament, prices are cheap lower. For this reason, FDM technology is a lot of attractive to several companies.

Less time overwhelming

Besides, compared to FDM technology, the other techniques need a lot of post-process. One doesn’t need to knock off powder or be very careful with pricey liquids. With FDM, nearly no post-process is required, the product is quickly prepared to be used.

Application

There are many commercial applications of FFF. It is used for rapid prototyping and tools manufacturing in many sectors. Using this method for prototyping is inexpensive and fast.

For example, it is used in prototyping scaffolds that are used in medical tissue engineering. It is a popular method of producing prototypes for form, fit and functional testing. The prototypes can be constructed directly from the materials.

Another major use of Fused Deposition Modeling is to make patterns for sand casting and molds that require lesser details.

FFF is also used to produce complex end-use parts in low volume.

Notes

Printers :

we use our Custom made 3D Printers. Maximum size are featured upto 500mm. Minimum feature size are 0.2mm.

Minimum :

Minimum Layer height are 0.1mm. Accuracy dependent (+- 0.1mm – 0.5mm). Tolerances: 0.05 to 0.20mm (+/-)

We are strongly advised that 3d printed part can be supported required therefore surface finish will effect.