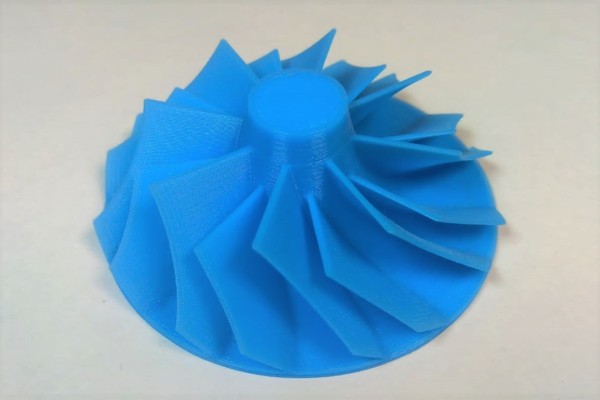

PLA

FDM PLA

PLA material is considered as the most widely held bioplastic material nowadays. Manufactured from sugarcane, corn starch, and other renewable resources, it’s used for a wide variety of purposes. You’ll mostly found Polylactic Acid in plastic cups and computer printings as well. We can also see its uses In making food containers.

Estimated Lead Time: 3 days

Post Process? Available

Max Build Size

700 x 700 x 700 mm

Default Layer Height

0.2 mm

Optional Layer Heights

0.1, 0.15, 0.2, 0.25, 0.3 mm

Tolerance

±0.2 to 0.5 % (with a lower limit of ±0.2 to 0.5 mm)

Heat endurance

Up to 55-60 ℃

Available Colors

Media

Advantages

- Gives more productivity than ABS material

- Comes with an excellent stiffness

- Best for 3D printing(Commonly known as popular materials)

- Can be heated and cooled easily

- Low-cost prototype.

Disadvantages

- Doesn’t work well in high-temperature environments

- Not as tough as other materials around

- Not a good option to be used in moving parts

- Complex designs with details

Note

Support structures are required generated to scaffold overhangs, which are manually removed after printing done. The support structure creates a rough surfaces.

Printing process are used nozzle 0.4mm and 1.75mm diameter filament.