DLP (Digital Light Processing)

DLP (Digital Light Processing)

Overview

DLP or Digital Light Processing is a 3-dimensional printing method. Just like stereolithography, it uses photopolymers. DLP produces parts with high accuracy and resolution.

However, it is different than stereolithography. Digital light processing employs a traditional light source such as an arc lamp that has a display panel as well. It is faster than stereolithography because it is used with the entire surface of the vat of the photopolymer resin in a single pass. However, DLP uses only a shallow vat of resin which lowers the running costs and levels of waste.

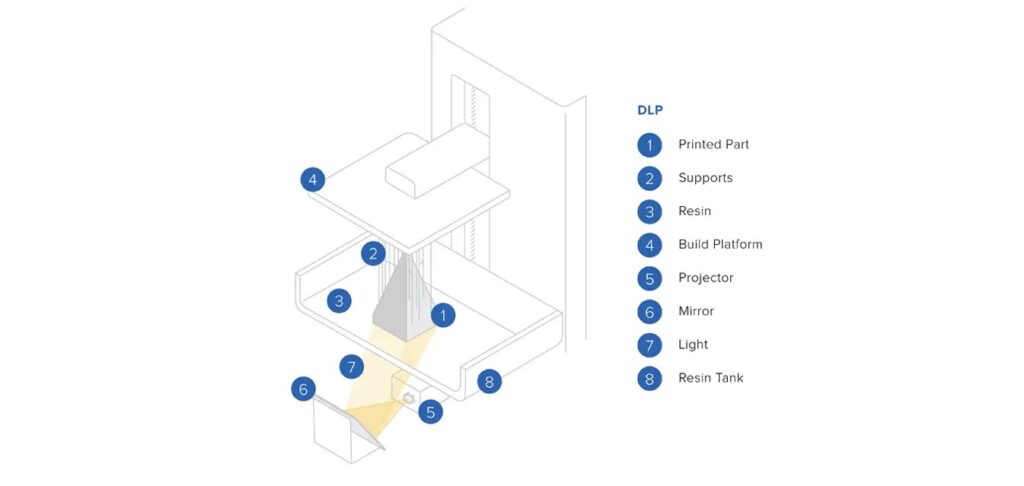

How does work DLP?

In DLP or digital light processing, a DLP projector exposes a vat of liquid polymer to light. This is done under safelight conditions. The DLP projector shows the image of the three-dimensional model on the vat of liquid polymer.

Once the exposed liquid polymer hardens, the build plate will move down. This exposes the vat to more light from the projector. This process is repeated in cycles until the 3D object is finished. Then, the liquid is drained from the vat, leaving the solidified 3D model.

Through this process, digital light processing is a faster printing method. The best thing about it as that it produces three-dimensional objects with an excellent resolution as compared to SL.

Benefits

Advantages

Digital light processing enjoys many advantages over other techniques. First, its high printing speed is exceptional. This is one of the most major differences between DLP and SL. A 3D file that is printing in 4 hours with the SL technology can be completed in half an hour with DLP.

Another pro of DLP is that it lets curing the whole surface of the layer at once. So, there is no need for post-curing.

The consistency of the printing model is another aspect that makes DLP a good method for production. DLP printers are more reliable than SL printers because they have lesser moving parts as compared to SL machines. This ensures the reliability of the system and keeps the quality consistent.

Also, DLP printers are cheaper than SL machines. So, DLP also wins the cost factor.

Application

There are many applications of DLP. It can easily produce patterns that will be used for investment casting. It can also make master copies for vacuum casting.

Furthermore, digital light processing is one of the best 3D printing methods available for designing models with complex and intricate geometries. So, it is a popular method in designing jewelry and helps in dental procedures.

Another useful application of DLP is its use in producing functional testing prototypes. It can be used for making visual prototypes needed for market testing.

Notes

Minimum :

Minimum Layer height are 0.03mm. Accuracy dependent (+- 0.01mm). Tolerances are vary 0.5%(+/-)

We are strongly advised that 3d printed part can be supported required therefore post process will be required.