Laser Cutting (Non-Metal Materials)

Laser Cutting (Non-Metal)

Overview

Laser Cutting (Non-Metal) is a precise manufacturing process that uses a focused laser beam to cut or engrave non-metal materials like acrylic, MDF, ABS, and plastics. It is ideal for producing intricate designs, prototypes, signage, and custom parts with clean edges and high accuracy.

This technique is widely used in industries requiring fast turnaround and fine detail, as the laser can cut complex shapes without physical contact, reducing material waste and minimizing distortion.

Laser cutting works by vaporizing the material along a controlled path, making it perfect for materials that are sensitive to heat or mechanical stress. It is especially beneficial when detailed patterns, sharp corners, or fine features are required on non-metal substrates.

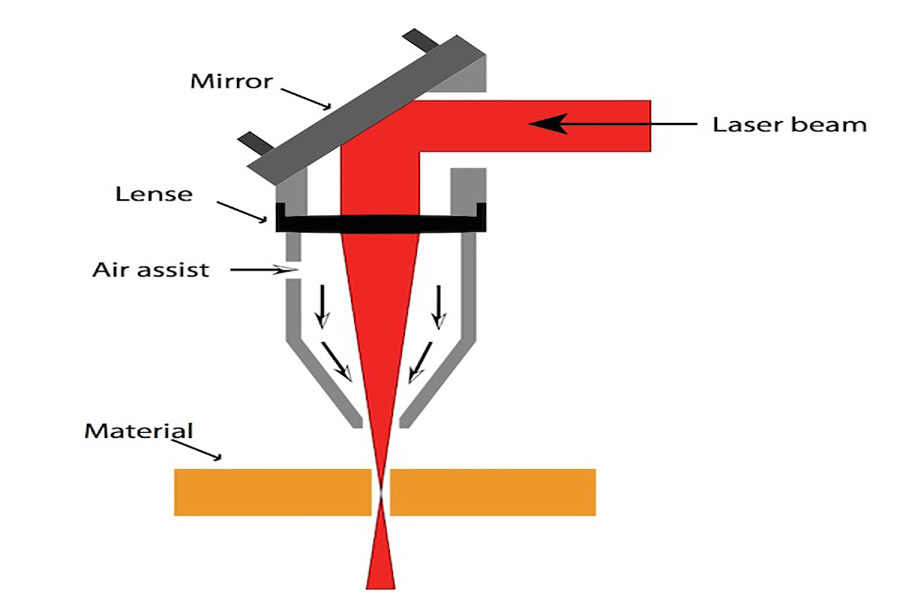

How Does Laser Cutting with CO₂ Technology Work (Non-Metal Materials)?

Laser cutting uses a high-powered, focused laser beam to cut through non-metal materials like acrylic, MDF, ABS, and plastics. The laser beam is directed by computer-controlled machinery, which follows a precise digital design to produce clean, accurate cuts.

The laser heats the material to a point where it melts or vaporizes, allowing the beam to slice through the material without any physical contact. This contactless process reduces mechanical stress and enables cutting of intricate shapes and fine details that traditional methods cannot achieve.

Because the laser’s intensity and speed can be finely adjusted, it can handle various thicknesses and material types, ensuring smooth edges and minimal thermal distortion.

Benefits

Advantages

-

High Precision: Cuts intricate and detailed designs with clean, smooth edges.

-

Non-Contact Process: Minimizes material distortion and mechanical stress.

-

Versatile Materials: Works with acrylic, MDF, ABS, plastics, wood, and more.

-

Fast Turnaround: Quick cutting speeds reduce production time.

-

Minimal Waste: Narrow kerf reduces material wastage.

-

Customizable: Easily adjustable power and speed for different thicknesses and materials.

-

Consistent Quality: Repeatable cuts with excellent accuracy every time.

-

No Tool Wear: Unlike mechanical cutting, laser cutting doesn’t wear down tools.

Materials

Materials Suitable for CO₂ Laser Cutting

-

Acrylic (Plexiglass)

-

MDF (Medium-Density Fiberboard)

-

ABS Plastic

-

Wood (Plywood, Balsa, etc.)

-

Leather

-

Paper & Cardboard

-

Fabric & Textiles

-

Rubber

-

Certain Plastics (like Delrin, Polycarbonate – check compatibility)

Notes

A3DXYZ offers top-quality CO₂ laser cutting services for non-metal materials. Contact our experts at A3DXYZ to learn more about how we can bring precision and speed to your projects.