SLS (Selective Laser Sintering)

SLS (Selective Laser Sintering)

Overview

SLS is an industrial 3D printing procedure perfect for manufacturing end-use parts.

In SLS, laser selectively sinters polymer powder elements intertwining them and constructing a section layer-by-layer.

SLS produces useful plastic elements with isotropic mechanical attributes that could be used for end-use and low volume construction or detailed prototyping.

It may seem like SLM. Both the techniques are similar in essence, but technically different. The material used in SLM us melted rather than sintered. Also, SLS is a newer technology that mainly aims to make prototypes and low-volume production of component parts.

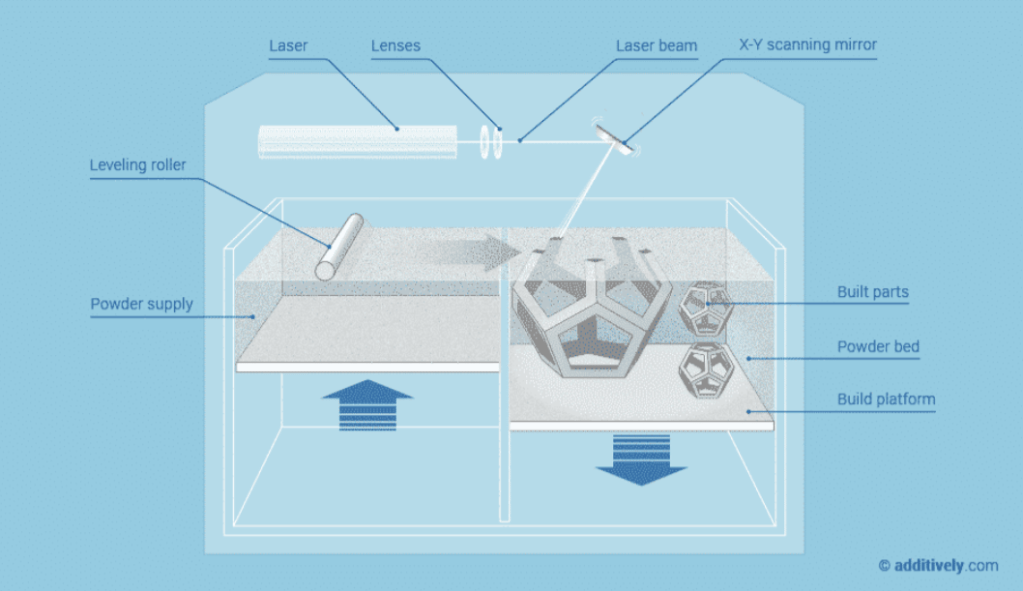

How does work SLS?

SLS uses a high-power laser like a carbon dioxide laser. It uses a pulsed laser to preheat the powder below its melting point.

It fuses small particles of the powder into a mass that has the 3D shape that needs to be produced. The powder can be made of plastic, glass, ceramic or metal. The laser fuses the powder on the surface f the powder bed. After each cross-section of the CAD file is scanned, the powder bed is lowered by a layer. Then, a new layer is coated on the top. This process is repeated in loops until the desired object is completed.

Benefits

SLS is becoming popular in many industries due to its long list of advantages.

The sintered powder bed lets you produce many embedded patterns and complex geometries in the object. For example, SLS can help you in making conformal cooling channels.

Also, the complex parts can be built easily without altering the surface from support removal.

The components produced using SLS have an excellent stiffness and possess high strength.

The parts also offer good chemical resistance. You can also use a wide range of materials with different functionality and durability.

SLS is also widely used for nesting.

The best thing about SLS is that it offers many possibilities for post-processing. For example, you can use coating, coloring, bonding, and metallization for the objects.

Choose SLS 3d Printing Services for:

- High-accuracy functional models from a wide scope of engineering materials

- low-volume production of parts for volumes of 1-300 units

- Cost-effective

- Isotropic parts with intricate geometry

From prototyping to small-batch production, the certified SLS 3D printing offices by a3dxyz will allow you to deliver highly accurate parts with quality and strength practically identical to injection molding. Call a3dxyz team to know more about our services.

Application

SLS is a popular technology in many production industries. It can easily produce many complex technologies easily.

It is widely used in making automotive hardware and wide tunnel models. SLS is also used widely for making end-use parts in the aerospace industry, military, and electronics hardware as well as medical equipment.

SLS is also being used for producing tools for other procedures. It produces jigs and fixtures that make other traditional manufacturing processes easier.

SLS has also been used by some artists. However, it is not used at domestic levels because it uses laser and the equipment is expensive.