SLA (Stereolithography)

SLA (Stereolithography)

Overview

SLA is well known and latest 3D printing technology that uses the photopolymer resins. It discovers the application in proof of theory models as well as designing parts and automotive styling. Despite the support structures, the SLA parts have a soft surface finish along with good dimensional correctness. SLA parts are as well used as expert patterns for the Vacuum Casting procedure.

Stereolithography or SLA is another type of 3D printing technology that is used to produce models and prototypes. It uses photochemical technology to create the object layer by layer.

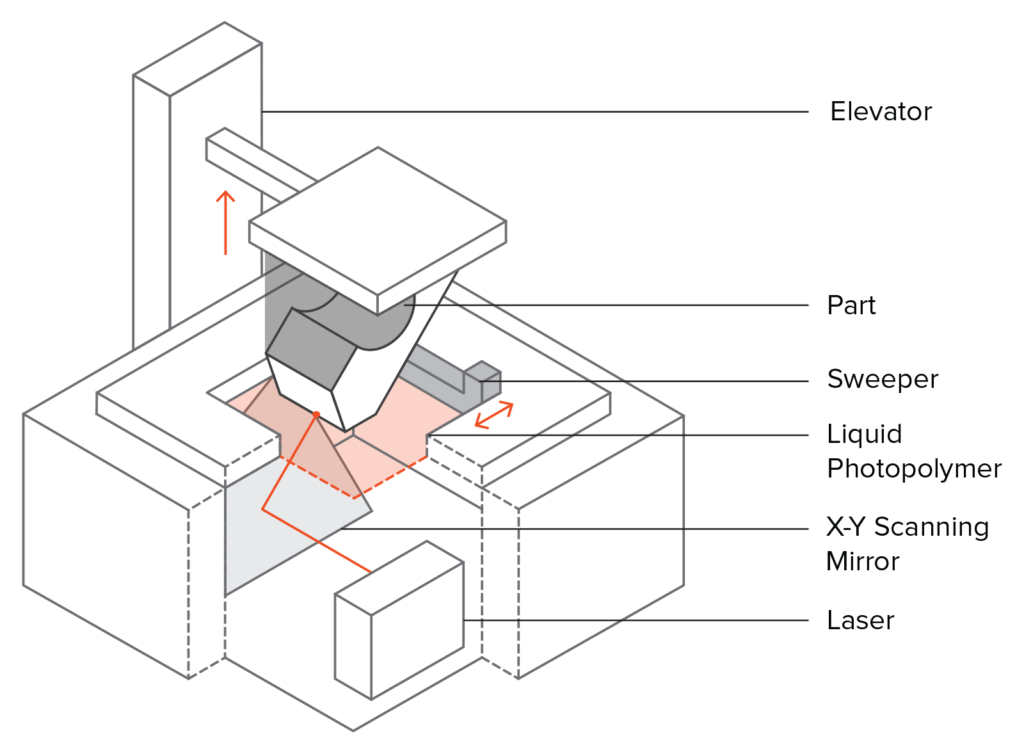

How does work SLA?

SLA uses light to form polymers from monomers and oligomers. These polymers link together to make a three-dimensional solid.

Using CAD, the ultraviolet laser draws a shape on the surface of the vat.

The resin is made into one layer using photochemical technology. Then, the surface is recoated with resin. This process is repeated for each layer until the three-dimensional object is completed. Once the 3D parts are done, they should be washed with a solvent to rinse off the resin from the surfaces.

Benefits

Advantages

One of the best things about SLA is that it is fast. You can produce a part very quickly, even within a few hours. The duration may increase depending on the complexity of the object.

Furthermore, 3D objects are durable and strong to be used in machines.

Less time overwhelming

Besides, compared to SLA technology, the other techniques need a lot of time of producing parts. With SLA, more depending parts can produce quickly at the same time when printing.

Application

SLA is most appropriate for the visual applications where smooth surface finish, an injection mold-like and a high level of characteristic details are essential.

Stereolithography is used in the medical field since the 1990s. It can create accurate models of the patient’s anatomy using the CT or MRI scan.

SLA also produces prototypes at a cheap price. Industries can use the prototypes to publicize the final product.

Notes

Minimum :

The minimum layer height is 0.03mm. Accuracy dependent (+- 0.01mm). Tolerances are varying 0.5%(+/-)

We are strongly advised that 3d printed parts can be supported required therefore post-process will be required.