3D Printing

admin2023-12-14T18:32:23+05:303D Printing a new technology

Table of Content

- What is 3D Printing?

- How does work 3D Printing?

- 3D Modeling Software

- 3D Model to 3D Printer

- 3D Printing Industry

- Application & Technologies

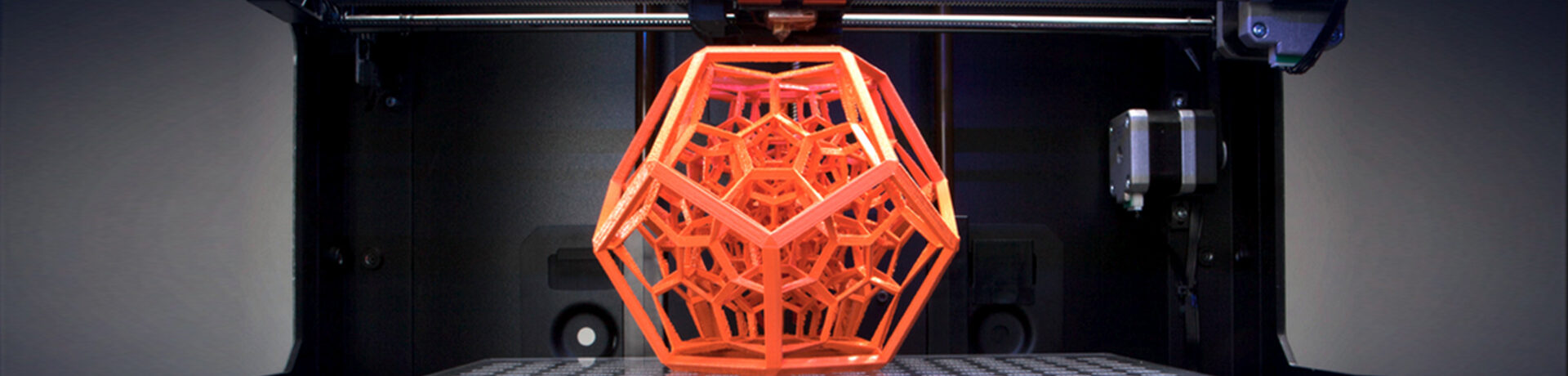

With the help of digital 3D models 3D printing technology employs layered printing so that tangible objects can be created. In simple words when someone has a blueprint of any object like say the Taj Mahal, a cup or even a bus one can get it printed in three dimensions. So, with the help of it you can easily print a replica of three dimensions of anything say the Taj Mahal or just a cup!

For this type of printing different raw materials are used and they include plastics, paper, wood, resin, and glass. With it things that were in your imagination will become real and you can touch them and feel them just like any original object.

Thus, even in the field of architecture it is possible to use this technology and make your customer satisfied. Let’s explore how you can utilize this system. We offer 3d printing services i.e. you can see how your project looks after installation.

During a 3d printing process, the entire object is converted into several slices and then arrange them from bottom to top. Those little layers remain to create a solid object. every layer is often very advanced, which means 3D printers will produce moving components like hinges and wheels as a part of the same object.

(Image Source : my3dconcepts.com)

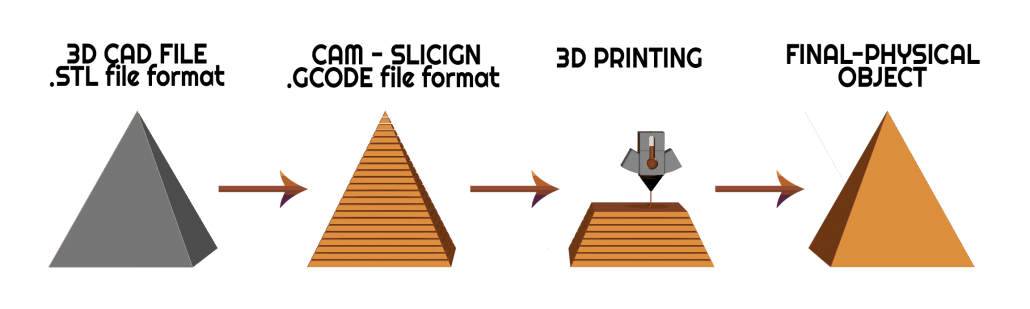

It all starts with creating a virtual design of the thing you wish to make. This virtual design is, for example, a CAD (Computer-aided Design) file. Using a certain modeling application the cad file is created or otherwise, we can use a 3d scanner to copy an existing object. A 3D scanner can create a 3D digital copy of an object.

Every 3Dimensional print begins as a 3Dimensional model generated in a modeling program. Years ago, we tend to had to pay much cash and time to acquire and learn modeling software package. Now, there are several easy-to-use modeling software system choices available, many of which are free. This list includes a number of the most effective options and is sorted by worth, with the free ones sorted alphabetically.

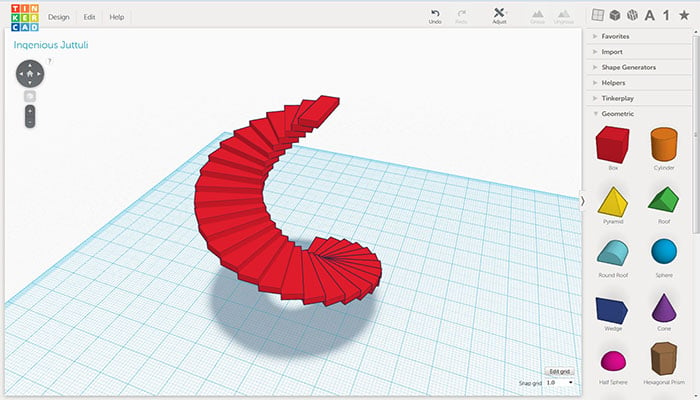

- TINKERCAD

Kicking off the list is TinkerCAD, an internet 3D design application which is good for beginners. It makes use of an easy block building concept, that essentially provides you access to basic shapes using that you’ll create your 3D models. that creates it a wonderful tool for making geometric designs.

TinkerCAD is fairly easy to get familiar with, and it additionally offers a bunch of wonderful tutorials to hurry up the training method. Once you are done creating a model, it helps you to share or export the file easily.

And if you do not own a 3D printer, you’ll additionally make use of its third-party printing service integration to get your model delivered to your doorstep in no time.

- CURA

Next up is Cura, another nice 3D printing application for beginners from Ultimaker, the number one manufacturer of 3D printers. not like TinkerCAD, Cura is a slicing software system for 3D printers that you’ll use to make a 3D model and slice it into layers as G-Code for the printer.

On top of that, you’ll additionally use Cura as a failsafe measure for your models. It will allow you to understand if there are any know problems model’s structure which may cause problems with the printing.

That feature could be a blessing for beginners since it ensures that you just do not waste any printing material or time on making models with structural problems.

By using a Slicing software the 3d model is divided into thousands of slices and then the original model is made. But before that, it is important that you must read the design guides and to know about the materials that you are going to use. And there is another main thing to consider that is the resolution of the file.

STL is the most common file format for 3D printing (which stands for standard triangle language), in this format that your design will be translated into triangles in a 3Dimensional space. Most 3D modeling software system has the choice to export your designs to STL file and set the required resolution.

3D Printing Industry is an international media company providing a good resource for all who are interested in 3D printing and 3D scanning. These two fields of technology that are fastly growing in relevance and application across industrial and consumer sectors.

These two technologies are playing a key role in the advent of a digital world, where physical meets digital.

The mission of the 3D Printing industry is to report on and build original content targeted around the latest developments in 3D printing and 3D scanning to stay our massive and growing audience informed technology breakthroughs, the newest applications and therefore the opinions of business insiders.

3D Printing industry works with a passionate team of skilled writers with a keen interest in 3D printing and 3D scanning. And the Media is very helpful to their customers and external contributors who are interested in look into 3D printing and 3D scanning. we tend to believe that this open mentality can encourage the dissemination of innovation and concepts. It echoes the open-source approach that has been thus successful within the software system industries over the last thirty years.

The best benefit from 3D printing tremendous opportunities 3D Printing Industry is helping our community by offering unique services and tools.

3D Printing holds a unique position in modern development. This technology is additionally called additive manufacturing. 3D Printing is often used in producing, medicine, architecture, custom art, and design, Automotive.

Additive manufacturing may be a broad term for a series of processes that build components in an additive instead of subtractive fashion. This means parts are designed up layer by layer rather than having material removed from a block. This approach to producing, as well as the several platforms related to the technology (including stereolithography, fused deposition modeling, selective laser sintering and more), supply a spread of unique benefits that a lot of traditional producing processes do not.

Application

Design freedom

Because components are designed up layer by layer in 3D printing, the method reveals unprecedented opportunities for design freedom, that successively creates opportunities for part improvement and lightweight. within the automotive sector, the flexibility to cut back a load of a component (and the weight of the vehicle) is important once attempting to boost fuel efficiency. 3D printing offers the flexibility to redesign and make automotive components that integrate advanced internal geometries, lowering weight and material usage while not sacrificing quality.

Part Consolidation

Beyond lightweight, additive manufacturing may also change manufacturers to redesign and consolidate parts—transforming multi-component assemblies into one part. This ability will contribute to progressively lightweight structures and may even improve the performance of a given part. within the automotive sector, consolidating components will facilitate to contour production and assembly processes.

Customization

When one thinks of automotive production, one usually thinks of mass manufacturing: refined production lines turning out lots of similar components before assembling them into cars. With the proliferation of 3D printing, however, the automotive business is currently seeing new degrees of customizability for cars at a viable price. For low-volume or specialty vehicles particularly, it’s currently possible to integrate custom interior features into cars at an affordable price. brand complete mini, as an example, lets customers select from a variety of personalized 3D printed interior components.

Rapid turnaround times

There are a variety of ways in which 3D printing will speed up automotive production. For one, within the prototyping stage, 3D printing is often used to quickly manufacture functional components for testing, enabling automotive designers and engineers to quickly confirm if a component’s design is viable. in the production stage, 3D printing is used by automotive makers for fast tooling, resulting in lower prices.

Consumer Product

In the commodity market, additive production has created new possibilities throughout the phases of practical prototyping, design, tooling, and even through series half production.

Education

Teaching advanced subjects is often very difficult because it typically needs loads of communication talent on the professor a prof to be able to draw a mental representation to the entire class. while learning turbomachinery or jet engine design its part of takes a while for college students to know that elements of the drawing are being referred to and it gets extremely hard to follow with everybody. A 3D printed model makes visual images a lot easier and helps breakdown harder ideas without stressing your imagination.