ABS

FDM ABS

When it comes to taking pride in depicting some exceptional mechanical properties, nothing can beat ABS. It never disappoints when it comes to displaying a spectacular sturdiness and strength. Thanks to the solid and strong nature, it possesses a spectacular exterior surface. Not only this, you’ll find Acrylonitrile Butadiene Styrene among the best stuff as an electrical insulator. So try your hands on it and see the difference.

Estimated Lead Time: 3 days

Post Process? Available

Max Build Size

400 x 400 x 400 mm

Default Layer Height

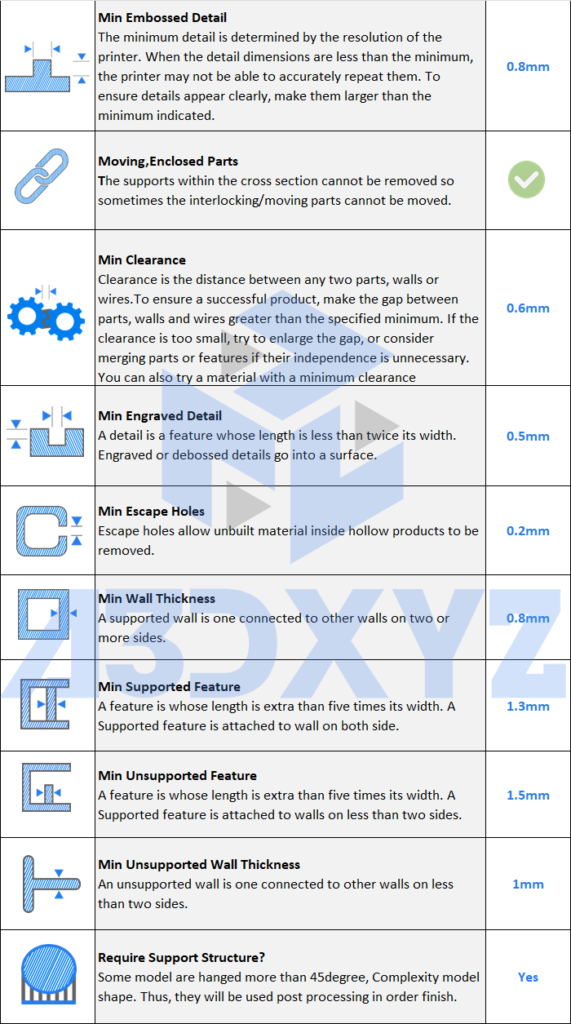

0.2 mm

Optional Layer Heights

0.2, 0.25, 0.3 mm

Tolerance

±0.2 to 0.5 % (with a lower limit of ±0.2 to 0.5 mm)

Heat endurance

Up to 100 ℃

Available Colors

Media

Advantages

- A great option for depicting models and prototypes

- A good option for using in moving parts

- Excellent stiffness and firmness

- Comes with brilliant insulating properties

- Withstands resistance perfectly

- Highly durable and proves to be strong and stable

- High surface quality and design

- Fights well against abrasion

- Shows a good heat resistance

Disadvantages

- Not a good weather resistant

- Gets scratched easily

- Grades catch fire easily

- The service temperature is low

- Prone to sudden failure due if comes in contact with grease

Note

Support structures are required generated to scaffold overhangs, which are manually removed after printing done. The support structure creates a rough surfaces. ABS are stronger than PLA and they are toxic(Not safe food).

Printing process are used nozzle 0.4mm and 1.75mm diameter filament.